- Index

- Brand

- Ams Racing (25)

- Chevrolet (160)

- Cncrsr (25)

- Comp Cams (66)

- Edelbrock (257)

- Engine Pro (33)

- Enginetech (62)

- Espeedpro21 (24)

- Gearhead (26)

- General Motors (24)

- Holley (313)

- Ict Billet (45)

- Jegs (26)

- Melling (35)

- Moroso (36)

- Motornets (32)

- Oe Quality (26)

- Proform (132)

- Speedway Motors (57)

- Weiand (46)

- Other (1404)

- Material

- 16 Gauge Steel (2)

- 304 Stainless Steel (3)

- Aluminum (477)

- Billet Aluminum (5)

- Cast Aluminum (116)

- Cast Iron (34)

- Chrome (4)

- Chrome Steel (3)

- Die Cast Aluminum (16)

- Diecast (4)

- Forged Aluminum (5)

- Mild Steel (3)

- Plastic (40)

- Polyurethane (2)

- Rear (3)

- Stainless Steel (56)

- Stamped Steel (18)

- Steel (91)

- Tri Armor Coated (4)

- Tri-metal (2)

- Other (1966)

- Model

- Partnumber

- Type

- Bearing Kit (10)

- Big Block Chevy (54)

- Camshaft (27)

- Cylinder Heads (10)

- Engine Block (30)

- Engine Mount Kit (16)

- Engine Oil Pans (18)

- Engine Valve Cover (12)

- Engine Water Pump (41)

- Exhaust Header (11)

- Fuse Box (56)

- Hydraulic Flat (33)

- Intake Manifold (115)

- Oil Pan (19)

- Piston Set (19)

- Radiator (47)

- Small Block Chevy (89)

- Valve Cover (32)

- Valve Cover Set (24)

- Valve Covers (28)

- Other (2163)

- Year

CHEVY BBC 540 555 STAGE 7.0 TURN KEY ENGINE, DART BLOCK, 724 hp

BBC CHEVY HYDRAULIC ROLLER CAM EXTREME TORQUE. TURN KEY 540/555 CUBIC INCH ENGINE 724 HP. You may have noticed other sellers using a similar name offering similar products. These other sellers have capitalized on our name as we see it, and many customers searching for us will inadvertently find them, thinking we are one in the same company. There is only one Skip White. Our official company name is Skip White Performance.

Please see the article in the lower part of this ad for a more detailed explanation. This engine comes fully dressed out on the front as pictured above. The carb, distributor, wires and starter are not included with this engine.

We have those items available in our other listings. Our engines can also be built for use in marine applications. Pictured below is one of our bbc engines in a customer's boat. We also offer our engines with a lower cost basic front accessory kit, with electric water pump option and with no turn-key options at all (base engine). See all our engine listings. We also offer our bbc engines setup with a blower as pictured below.WISECO FORGED PISTONS AND SCAT COMPETITION SERIES RODS, NEW GENERATION DART BLOCK, BRAVO ALUMINUM HEADS. FULLY ASSEMBLED FROM INTAKE TO OIL PAN. Our 540/555 Hydraulic Roller cam engine will produce 724 horse power at approx. The build sheet is at the lower part of this listing.

This engine is an excellent choice for use in classic street rods, sport trucks, 4x4 trucks, and can be used as a daily driver. High mileage use is not a problem with this engine. This is engine may also be setup for use in larger work trucks, or motor homes. We can also set any of our engines up for marine use.

This engine will produce nearly triple the horse power of the original bbc 396, 427 and 454's and much greater torque. For those wanting to put this engine in a classic car or sport truck, select cam choice # 1 or # 2 with the Hurricane intake. This engine will deliver very impressive power in the lower rpm range, and have a very high degree of drivability and long life. This engine uses a brand new Generation Dart Block, (standard deck height) with all new internals. This engine is designed to have a very high level of drivability, or street manners. Here are a few good reasons why we think the Stage 7.0 engine is a better choice than any of the original equipment big block engines produced by GM. The Stage 7.0 bbc engine will accelerate any heavy car much better than any of the underpowered original GM bbc engines. The exhaust note from this big block engine is much deeper than that of the typical stock GM big block engines.Installing this engine in heavy cars or trucks without killing acceleration, or having to deepen the final gear, and needing a huge stall converter is a real plus. This engine will accelerate a 7500 lb vehicle much better than any stock bbc engine. Low maintenance and high drivability even in very heavy cars and trucks, while generating up to 724 hp at the same cost as building a 496 engine. You don't have to turn the engine to a critical rpm range to produce its max hp output. There's nothing unsafe about running an engine that's well built like this up to 5,800 rpm.

The hydraulic roller cam is very reliable and will not require a bronze distributor gear, as it has a normal cast gear. Our aluminum heads use very high quality hardware. All of our valves are from PBM, and are considered to be very high quality valves. Should you ever decide to sell your car, or truck with this engine, the resale value would be much greater.We do a full test run using an engine test mule on every engine we build. The engine is run for two intervals of 20 minutes each, and every possible issue is addressed. When you receive the engine, it will be ready to install and run. We also include an engine stand as pictured, wheels included, and an engine lift plate. As of 10/25/2016, we completed installation of our second brand new Super Flow 902S dyno.

This dyno is dedicated for dyno testing and tuning on our bbc engine line only. De-tuned engines with different cam and intake combos will move the torque into the low rpm range, and is very desirable if you're sporting around on the street, rather than all-out racing. The de-tuned version of this engine will also allow you to set the car up closer to stock and increase drivability to a very high degree. Throttle response is also noticeably better.

We can help you with a cam and intake selection that best suits your needs. The compression range will be approx. 10.5:1 depending on how we set it up based on your needs.

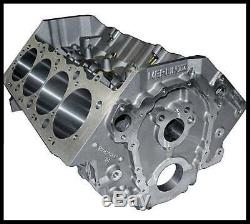

The Wiseco forged pistons are highly resistant to the damaging effects of detonation. The build sheet is as follows. BBC NEW GENERATION DART BLOCK BORE 9.800 STD DECK HEIGHT. We now use the New Generation Dart blocks in our BBC 572 engine builds. The New Generation Dart block is light years ahead in overall construction as compared to any of the other blocks on the market.

Dimensional specs are spot on, and this has been an issue with other blocks we have used in the past. Many of the top engine builders, ourselves included, have found the new Dart block to be superior to the earlier generation Big M series Dart block in many ways. Dart Machinery has completely redesigned the Big M series Block. They have incorporated numerous improvements and new features to virtually every area of the block. The block is bored to size with our new Centroid touch probe machine. Few machine shops have a machine of this accuracy. We also deck the blocks to an RA finish of approx.The decking procedure is also done by our Centroid CNC machine. We often find many brand new blocks to have a sloping deck of up to 4 thous. When we're finished decking the block, it is within approx.

001 accuracy from end to end. Many machine shops fail to catch this as the machinery they use does not allow for such accuracy. We then plate hone the block with our new Sunnen SV10 diamond hone machine. This is also a very advanced machine that hones the block with a finish unlike conventional machines. The final step is to clean the block in our high pressure block washer.Below are the specs of the rotating assembly portion of this engine. The picture above is a file photo of the rotating assembly that comes with this engine. See the detailed info below for the actual pictures and items included in this engine. Crankshaft Material : Cast Nodular Steel.

Rear Main Seal: 2 pc RMS. Rod Type: Scat Pro-Competition, I-beam, Bronze Bushed. Rod Material: Forged 4340 Alloy.

Rod Bolt/Cap Screw: ARP 8740 Cap Screws. Pistons: Wiseco Fully Forged, with a fully machined crown. High Performance for street/strip use. Piston Size: 4.500" when configured as a 540 cid or 4.560" as a 555 cid engine. Ratio will be right at 10.5:1. Piston Material: Forged 2618 Aircraft Alloy. Piston Rings: Mahle High Performance, Moly, Standard Tension. Ring Size: 1/16 1/16 3/16. Bearing, Damper, and Flexplate Specs.Balance: In House on CWT balancer. Damper: Pro-Race brand SFI 7.0.

Flexplate: Heavy Duty SFI 168 tooth or 153 tooth. Listed below is a complete breakdown of all the parts that are included in this engine. WISECO FULLY FORGED PISTONS, RATED AT 800+ HP.WISECO PISTONS ARE 100% MANUFACTURED IN THE USA. THEY ARE ONE OF THE HIGHEST RATED PISTON BUILDERS IN THE COUNTRY. The Wiseco forged pistons are rated very high in the street/strip performance industry. Are made using the 2618 aircraft alloy and have fully machined crowns. We prefer the 2618 alloy over the lower cost 4032 alloy.

This alloy may fragment from the effects of detonation and if this happens, it can be very destructive to the engine. Those types of pistons are fine for stock or mild engine builds, but should never be used in carbureted engines built to high horse power levels.

The forged 2618 alloy piston is much more resistant to the effects of detonation and heat. Our Wiseco Forged pistons are custom designed with an increase in compression height. Here are a few facts about compression height and deck height. Our custom made pistons have a compression height that is.010 taller on bbc pistons, and. 015 taller on sbc pistons, as compared to most all of the catalog pistons on the market. We find this to be a very valuable feature.

Since our pistons sit at a taller than normal compression height, we only have to remove approx. 005.010 off the deck surface of the block. Our goal is set the piston at zero deck (flush with the deck surface).This maintains the deck's thickness, making it much stronger than a block that has been cut down. The engine will also run a bit cooler with a thicker deck. It's well known that the deck dissipates much of the built up heat an engine generates.

This also allows for future deck re-surfacing without compromising the integrity of the block. On our bbc engines, we actually leave the piston about. 005 in the hole to allow for possible piston rock. Our sbc engines will have the pistons setting right at zero with the deck.

You may have noticed that our Wiseco custom made forged pistons are referred to as Racing Pistons on the package. This does not mean that the pistons are for racing only. This is a generic term, referring to their ability to be used in high performance applications as well as for street rod use. These pistons are perfectly designed for use on the street, as well as for medium to upper level drag racing. We have built approximately 5000 engines using the Wiseco pistons.

The engines have been for street rod and strip use. We have seen no problems, nor have there been any complaints. They are an excellent product in every respect. These pistons are also suitable for use with nitrous or blower setups. The picture below is a file photo of our Wiseco pistons.

MAHLE HIGH PERFORMANCE MOLY RINGS. The picture below is a generic file photo of a Scat crankshaft.

Some of the benefits of the Scat crankshaft supplied with this assembly. The material used in this crankshaft is manufactured from an exclusive Space Age material that was designed for high strength and fatigue resistance. The Scat cranks are the best value you will ever find. The Scat crankshafts are the best way to build a strong bottom end for, street rods, dirt and circle track racing, and drag strip racing.This crank is suitable for use up to approx. Pictured below is our ABS crank polishing machine in action. We polish the crank on every engine we build.

This extends bearing life, keeps oil cooler, and with the reduced friction, a slight increase in horsepower is gained. Many machine shops fail to do this. The finish on most cranks are at the bare minimum of acceptance, and we know this can affect bearing life. We have measured the RA finish with our profilometer, and found it to be as high as 25 RA finish on many of the cranks. We bring that number down to below considerably.

We now use the Clevite bearings in our engines. Our choice of rods are the SCAT COMPETITION SERIES rods with ARP-8740 cap screws. The Scat Pro-Comp extreme duty I-beam rods should not be mistaken for ProComp rods.

These rods are made exclusively by Scat, and have nothing to do with the ProComp company. The critical sizing and installation of the ARP cap screws is performed on a Sunnen machine in the USA by Scat Industries. These rods are excellent for those wanting the extra security offered by a rod with 7/16 ARP cap screws. Take notice of the design of these rods. They are far superior to conventional style I-beam rods. If you do a search on the Scat Pro-Comp rods, you will find a vast amount of info on many car forums. All of the info is 100% positive. These rods are run in engines that not only produce high horsepower levels, but also run at continuous RPM. Notice the general appearance in the pictures. These rods do look impressive. The style is reminiscent of a steel billet rod. The fact that these rods are incredibly strong and well made, coupled with the fact they are light weight, made it an easy decision to use them in all of our high horsepower street/strip engines.We have noticed some engine builders using low cost generic rods and crankshafts in their engines. These non-branded, (no-name) products are often poor quality in many ways.

You will notice many of the low end engine builders fail to mention the actual brand of the rods or cranks used in their engines. Upon further investigation you will find such parts not to be a branded name product. They may label these parts with a name, but one that is totally unrecognizable in the industry. Our experience in years past with such rods and cranks has been disappointing to say the least. Besides the obvious issues such as incorrect sizing and machining that is difficult to correct, the questionable alloy these items may be produced from and the potentially incorrect heat treating methods used, could prove to be disastrous. Little can be done to verify this and nothing can be done to correct it. Failures of such critical parts will usually result in catastrophic damage to the engine. As you may have noticed, this is why we specify the brand name, and series of every part used in our engines.Many of the inferior "no-name" rods on the market will also have "no-name" rod bolts in them. We have seen these bolts before, and they are very low quality.

They don't have ARP's rolled thread design, and they don't torque down with the same characteristics as a genuine ARP bolt. It's not just a matter of having a different brand bolt in the rods; these bolts are low quality in many ways.

They have been known to fail in engines to a much greater degree than a high quality rod bolt, and this failure usually causes catastrophic damage in the engine. Beware of rods that don't mention the rod bolt brand. As far as we're concerned, ARP bolts are the only brand we would ever use or accept in a set of rods. Genuine ARP 8740 cap screws. PRO RACE BRAND SFI HARMONIC DAMPER, 7.0 DIAMETER INCLUDED. Pro-Race brand dampers are used on all of our engines. We have noticed others using a low grade knockoff brand damper/balancer, and we have encountered them in the past. They are substandard in appearance, and are often out of spec. The timing marks were also poorly marked on some of the balancers we have come across.Another problem with low grade dampers is the elastomer bonding can lose its adherence to the inner and outer structure. This problem is referred to as a slipped damper. We have only encountered this once in 10 years with the Pro-Race brand dampers. VERY FEW SELLERS FINISH OFF THEIR TURN KEY ENGINES AS WE DO.

We did not offer this billet timing pointer in the past. However, we noticed that there was a birds-eye view of the timing pointer from the driver side of the engine, so we decided to use these on all of our engines.

HEAVY DUTY SFI RATED FLEXPLATE MADE IN THE USA INCLUDED. This SFI flexplate is made in the USA and will resist cracking and warpage to a very high degree.

One good telltale in identifying a low quality flexplate is the lack of welding on each side where the plate mates to the ring gear. They usually have a pale grey color to them, as they are not coated, and will rust quickly. Ours are welded on both sides, and are much thicker than an OE plate, and are zinc dichromate coated. We do offer this engine with a manual flywheel.In most cases we do have both sizes, 153 and 168 tooth, available. We do our own balancing with our new state of the art CWT 5500 Series balancers. The CWT 5500 is the ultimate for precision balancing. We now have three of these in our machine shop. We consider this machine to be highly advanced compared to the Hines balancer we once used.

We balance every rotating assembly we sell within 2 grams or less at no extra charge. A balance sheet is included with your assembly. Three CWT balance machines under one roof is a rare sight. Our crew wrapping up for the day. Assembled by us with premium PBM competition grade valves, Melling springs, Comp retainers, Comp Viton valve seals, Comp spring ID locators, Comp 10 degree locks. Notice the multi angle valve seat cut. These heads are designed to very high standards.Below are the actual flow numbers for the Bravo heads. These numbers are true and accurate. The testing methods we use are considered to be on the conservative side.

Some choose to show flow charts for their heads that have been done in a way that shows numbers that are misleading in our opinion. We use the Bravo heads on most all of our bbc engines builds all the way up to the 572 engine. The horse power numbers they produce are exceptional as compared to any of the low to mid range priced heads on the market. Fel Pro 1057 premium race grade series head gaskets, ARP head bolts, and rocker studs. ARP HEAD BOLTS AND WASHERS AND ROCKER STUDS.

The new Ultra Pro Magnum Roller Rocker Arms not only live up to the lofty standards of the original Pro Magnums, but they also take stud mount rocker performance, stability and value to a whole new level. The modern arched, web-like design delivers increased strength and rigidity while still reducing the moment of inertia and optimizing the dynamic balance. If you've read our warning on engine builders using low grade no-name rods and cranks, a similar situation exists in the roller rocker market. We do not use or sell off-shore, (no-name) roller rockers, period. They have proven to be faulty in many ways.

The center trunnions are not polished, nor is the center of the roller tip true to size or polished. Metal fragments are often left inside the trunnion housing and will cause destruction of the needle bearings. The aluminum alloys used are never aircraft aluminum alloys as are used in all USA made roller rockers.

They often mention the alloy as being 6061, and that is a very soft form of aluminum. The 6061 alloy used on these will assure rocker-flex on any higher than stock spring pressures, and this will affect performance. The pins and keepers that hold the parts together are often of poor quality and improperly installed. The front roller will usually scoot along the valve tip, as it can't roll properly due to rough internal surfaces. We have honestly seen valve tips that were scalloped out due to the front roller dragging across them.

This will cause the valves to side-load against the valve guides in the heads and surely cause damage to them if run like this for very long. We have scrutinized these products in the past and found all of the above problems, and I can tell you there are most likely many more.

We would not use them in an engine under any circumstances. You will also see many of these rockers made from stainless on the market. They use a low grade stainless that actually has a near non-existent amount of nickel in them, but that's not the real problem with them, as stainless steel has no advantage over high grade heat treated steel when it comes to a roller rocker.

The lack of hardness of the rocker body is the real problem. The problems with these stainless rockers are the same as mentioned above. They are pure junk, in our honest opinion.They could possibly be used on a budget back yard stock build up that has a very low spring pressure, with a cam that has very low lift, but then you would be better off with the stock stamped rockers on such a build. We have heard of many engines using these rockers that came apart and spilled needle bearings into the engine, only to end up in the oil pump. It seems like some engine builders do not care how long the parts in your engine last, or they simply don't know this. I can tell you for sure that using such low grade, "no-name" roller rockers is asking for trouble. We use Comp Ultra Pro Magnum rockers in all of our BBC engines.

The difference in these compared to the low grade no-name rockers on the market is huge. Premium Morel Hydraulic Roller Lifters.

We use Howards brand premium pushrods in all of our engines. They are lightweight in design, yet very strong. Made in the USA from 4130 chromoly steel. Regular hardened pushrods will most likely flex in the engine when running above normal RPM ranges, and risk bending under high RPM. These do not have the welded ball on the end.We only use the swedged one pc. Design, which is a well proven design far superior to the style many others use in engines. 4130 chromoly steel is also much stronger, and will resist flexing.

When a pushrod flexes in the engine, you lose lift. Don't be misled by the term "hardened, " as this is nothing more than a stock style low cost push rod. They will flex in the engine or possibly bend permanently. Our choice of lifters are the Howards brand tie bar lifters. These lifters have many unique features. Pictured below is our Speedmaster single plane intake. We also offer the Edelbrock satin RPM Air Gap intake as an alternate choice at no extra charge. 304 STAINLESS ALLEN HEAD INTAKE BOLTS ARE USED ON ALL OUR ENGINE S.We are offering three cam choices listed below in this engine. Cam Choice # 1 By Comp Cams. Cam choice # 1 offers fair drivability and mid range power. These factors are highly dependent on car weight, gearing and stall speed.

Valve train stability and longevity is fair with this cam but not recommended for excessively high mileage use. Power comes on with this cam at approx. Max power will be achieved at approx. You may use the single plane intake with this cam to achieve max top end horse power numbers.We recommend a stall converter in the 3,000-3,500 rpm range. Final gearing when used in a car or sport truck could actually be in the 3.55 range or numerically taller. Overdrive use will most likely not work with this setup. This cam combined with a single plane intake is not suitable for cars running air conditioning or power brakes or to operated in overdrive.

Many factors come into play as to what cam and intake you should go with. Continue reading the info in the cam choice section below before selecting a cam and intake. Official Dyno Results on Cam Choice 1 in our 555 engine with a single plane intake and our new 335cc rectangular port heads. This is an excellent cam and head combination. Our new 335cc bbc heads have proven to be exceptional.

Official Dyno Results on Cam Choice # 1 in our 555 engine with a dual plane intake and flat top pistons. This engine had the low compression, (9.56:1) flat top pistons, and our former line of cyl. Our new heads would have possibly exceeded these numbers especially with normal compression ratio. This setup would have been better suited with the Cam choice # 2 from what we're seeing. Low compression setups are for very heavy vehicles, and smaller cams are more in line with such setups.

The smaller cam would have made better off idle power. Cam Choice # 2 By Comp Cams. Cam choice # 2 offers a slight increase in bottom end torque compared to cam choice # 1. This cam selection is the best choice for cars that have medium to tall gearing. Very good acceleration with improved street manners. The peak horse power falls about 15-25 under cam choice # 1.This cam would also be excellent for medium to slightly heavy vehicles up to approx. Max power is achieved at approx. This cam has been very popular for those more concerned about drivability and outright longevity of the valve train and engine engine. The valve train wear with this cam would be very low.

Off idle power is improved as compared to cam choice # 1. We see no drawbacks to going with this cam. The power in the mid rpm range is very good. Vacuum may be enough for operating power brakes. Official Dyno report with this cam choice, Bravo heads, a single plane intake, and an MSD distributor. Cam Choice # 3 By Comp Cams. Cam choice # 3 offers a huge amount of bottom end and mid range torque. This cam selection is the best choice for cars that have very tall gearing or operating in overdrive. Very good acceleration with excellent street manners. The peak horse power falls an additional amount of about 15-20 under cam choice # 2. This cam would also be excellent for heavy vehicles, quad cab 4x4 pickups up to 5,500 lbs. The valve train wear with this cam would be virtually non-existent. Off idle power would be excellent.The power in the low rpm range is amazing. Vacuum should be enough for operating power brakes. Long range cruising and operating air conditioning is not an issue with this cam. This cam will still have a mild lopey idle but smooths out rather quickly at about 1,800 rpm. We have several different options in valve covers.

Here are our most popular choices. These are just a few of our popular valve covers you may choose from. We do have several more choices to select from in our other listings at no additional cost. If you chose cam choice 1 or 2, then we highly recommend using an exhaust evac. The vacuum created by the engine is somewhat insufficient when using these larger cams, heads, carb and intake to operate a pcv system at its best. The exhaust evac system will pull the crankcase gases out of the engine at a very smooth and controlled rate. This allows the rings to seat in much faster and better, and can increase horse power to some degree by reducing crankcase pressure. Another benefit of the evac system is that you're not contaminating the fuel and air mixture with semi-burned byproducts from the engine oil and combustion process.After the engine is completely broken in, the pcv setup may be sufficient. However, it may not be the best choice. The break-in time may also be slower with the pcv setup.

We also offer a vacuum pump system for the ultimate in crankcase pressure control. If you do decide to use an exhaust evac system, we have a few more recommendations. The bullet style perforated mufflers, like those made by Magnaflow and many other companies, must be used. In our opinion, they sound the best and, most importantly, they allow the exhaust evac system to work properly.

Magnaflow is a popular brand of the true straight through mufflers, and there are several other brands on the market such as Corsa, Borla, and Bullet. The sound level is controlled by the length you choose. The 12-16 inch length sounds the best to us. These mufflers have smooth perforated inner walls. They should not be confused with traditional glass packs with fluted walls, which are very restrictive and have a somewhat sloppy sound. Traditional chambered mufflers, like Flowmaster, create a back pressure pulse that will interfere with the operation of an exhaust evac. Chambered mufflers have the reputation of helping bottom end throttle response, but you will have a decent amount of bottom end power with this engine, especially if you have chosen cam choice 2, 3 or 4.In our experience, the straight through perforated mufflers sound and perform better in every respect, and allow the proper use of an exhaust evac. Timing components: SA Gear 8999T billet double roller timing set. We use the top of the line SA Gear timing set with a torrington bearing and rolon chain. The difference in quality is dramatic compared to the common low-cost timing set.

The upper sprocket is made from billet steel and the lower is induction hardened with nine keyways. These sets are hand matched for selective sizing. Should you ever want to confirm that this is what is actually in your engine, you can remove the timing cover, and you will see that this timing set is very different in appearance to the run of the mill low cost sets often used by others. This timing set is offered in three different chain tension setups, allowing us to set it up perfectly every time.

One more benefit is that timing accuracy is very precise and will remain that way. This timing set will likely last for the life of the engine. This is what you will find in most solid roller engines, as they have very high spring rates, and create an enormous load on the chain and gears, compared to non solid roller setups. It may seem like a bit of overkill to use such a high end timing set, but the versatility and extreme quality outweigh the cost, in our opinion.The oil pans we use on all of our engines are made in the USA by Champ. The Champ oil pan has a full windage tray, crank scraper, and trap door. The oil pan is made from a thicker than normal gauge material, and has embossed ribs in the body. The 7.5 qt Champ oil pan has kickouts that swell outward approx.

3 inches on each side. If you think you will encounter clearance issues with the kickouts, we recommend opting for the stock appearing 6 qt.

Pan will still be a Champ pan and will have the windage tray and crank scraper. We strongly recommend reducing the amount of oil used in these oil pans by approx. 1/4th to 1/2 a quart. Doing this may greatly reduce the chance of oil leaks, and reduce oil temps. The larger counter weights used on stroker crankshafts are why we recommend reducing the oil capacity in these engines.

To be clear on what we're saying, we would like to see you add right at 7.0 to 7.5 quarts of oil grand total in your engine and oil filter when using the higher capacity oil pan that has the flat ribbed bottom with kickouts on the side. When using the stock appearing oil pan, we would like to see you add right at 5.5 to 5.75 quarts grand total in your engine and oil filter. Our engines include a dipstick. It's very important that you re-calibrate the oil level marking on the dipstick.

This is due to the fact that the dipstick, oil pan, and block are all made from various manufacturers and we often see great variances. Couple this with the fact that you may be running a reduced amount of oil, and the "full" mark on the dipstick will most likely not indicate correctly.

Once you have put a predetermined amount of oil in your engine, and run it for a few minutes, let it sit for awhile on level ground, check the oil, and mark your dipstick with a flat file to re-establish the full mark. The quality of these pans far exceed any of the lower priced oil pans used on many engines. We do not use the knock off oil pan gaskets on the market.Felpro premium oil pan gaskets are used on all of our engines. Pictured below is a file photo. The actual Felpro gasket used will be the correct model for this application. We use our premium studded mini nut set on all of our oil pans and valve covers.

The nuts have a serrated face and built in washers. This is the ultimate set for securing the oil pan and valve covers to the engine and is far superior to the typical bolts used by most other engine builders. Our standard engine color is black. Custom paint work on engine blocks and oil pans is available as an optional upgrade.

The pictures above and below are file photos to display the studded mini nuts. Other items seen in these pictures may not represent your actual engine. Melling M-Select Oil Pump, and M-Select Drive rod with ARP stud. The M-Select series oil pump by Melling has several important upgrades compared to the regular Melling M-55 Series.

The gears are billet steel, and the body is stronger, coated with corrosion-resistant nitrite. This oil pump also includes the M-Select drive rod. Both components are far superior to the regular Melling oil pump and drive rods used by most other engine builders.

Pictured below are the front end accessories that are included with this engine. They will be installed on the engine. This is our satin high volume long style water pump with aluminum impeller. This is a very high quality pump. Our 120 amp chrome plated one or three wire alternator.

Chrome plated power steering pump. We are confident that the price we have on our engine will never be matched by our competition! We include an engine lift plate and heavy duty engine stand with casters with every engine we build. We offer this engine with selected upgrades and options. Listed below are some of the most requested ones.

Many not only improve performance, but further enhance the reliability and longevity of your engine, along with resale value. Edelbrock Pro-Flo 4 XT EFI System. This has become a very popular upgrade on many of our engines.

For those not wanting to deal with the potential quirks of a carburetor, this is the way to go. This is a true fuel injection system with 8 injectors, (one per cylinder). Drivability becomes vastly improved over a carb or standard throttle body efi. Throttle response in the low to mid rpm range is superior to that of a carburetor. Startup and warm-up are also greatly improved.Tuning stays spot on regardless of altitude or weather conditions. These systems make it very easy to tweak the tuning on your engine to better serve your application. Our engine room crew has found the Edelbrock Pro-Flo system to be a very straightforward setup. This system comes with its own high energy variable ignition system.

The timing is controlled through the built in ECU. The Pro-Flo system has a slightly higher cost, but is well worth it, in our very strong opinion. Our company founder, Skip White, stated that he has no problems with running a carb on a street rod engine, but the ability to tune the engine to perfection and the fact that fuel metering is so perfect with the Pro-Flo system has changed how he thinks an engine should receive its fuel and air, and variable ignition timing allows for max power when driving under optimal conditions. The difference in drive between the two is vast, to say the least.We have installed approximately 50 of these on engines in our dyno room, and have yet to encounter any problems. This system provides you with a high performance Pro-Flo XT-style intake and 90mm throttle body. Unlike regular throttle body EFI systems, Pro-Flo 4 features the fuel rails and individual injectors for each cylinder mounted on the manifold. This Edelbrock design produces the best fuel atomization and distribution for the ultimate performance, as well as delivering the most control and the most efficient way to deliver fuel to your engine. Along with innovative design, Pro-Flo 4 systems have the latest technology with an all-new ECU, and even more features for advanced tuning, with the key being their exclusive E-Tuner app with base calibrations developed on their dyno.

Cost for this upgrade is calculated by taking the retail difference between the intake manifold that comes with this engine and the retail cost of the Edelbrock Pro-Flo System. This is a great value with many benefits, in our opinion. SFI Rated Billet Steel flywheel upgrade/option for manual transmission. Upgrade to a SFI billet steel flywheel 168-tooth or 153-tooth for manual transmissions. We highly recommend the SFI billet steel flywheel for those running hard.

These are fully cnc'd and far superior in many ways compared to the regular cast iron flywheel. There will be a Chevy 153 tooth and a Chevy 168 tooth size available. Be sure you know the size you need. BBC Scat H-Beam Rod upgrade from Competition Rods: Recommended for those running hard. The Scat Competition rods that come with this assembly are sufficient for most street rod uses, but the Scat H-beam rods will most likely offer more security against rod breakage under hard use. ARP-2000 rod bolts: This is one upgrade that we find to be very valuable. The rod bolts are most likely to fail under hard use, moreso than the rod itself. When a rod bolt fails during high RPM, total engine destruction is usually the result.The ARP-2000 rod bolts are a very good upgrade, in our opinion. We actually have few, if any, problems with the regular ARP-8740 bolts, but those who run hard always upgrade to the ARP-2000 rod bolts. The ARP-2000 rod bolts also torque at a higher number, and this increased clamping force is also a factor in keeping the big end of the rod stable and true to size. The ARP-2000 bolts are installed in the rods and this upgrade is only available with the Competition rod upgrade. This is the ultimate upgrade for those wanting to run hard.

Nos, blowers, turbos, are not an issue with this crank. Even without such power adders, this Crank offers great protection under the most severe conditions. This upgrade also comes with the HP high Performance King bearings.

Should you decide to run power adders in the future, this would be essential. The fatigue life of the 4340 crank over the cast nodular is also greatly extended.We do offer this upgrade as part of many of our assemblies in some of our other listings. They have the key words, "fully forged, " in the title. Polished Speedmaster intake upgrade: The polished intake upgrade is very popular, and certainly adds a bright fresh look to your engine.

Dyno Tuning: This is one of the most important upgrade/options we offer. There are many benefits to this service. The engine is first run at fast idle to bring the water and oil temp up to normal operating temperature. It is then run for approx. 20 minutes under a simulated load at around 3k rpm to promote initial ring seating.

After this, the engine is shut down to allow us to check the readings on the spark plugs, and for any possible oil leaks. This cool down is considered part of the engine's first heat cycle. We then follow up with multiple low to medium rpm runs to further the break-in process of all the moving parts in the engine. During these multiple runs, we are paying close attention to the EGT, (exhaust gas temp) readings, vacuum pump readings, oil temp and pressure, coolant temp, and overall engine sound.At this point, we start the actual dyno tuning process and this focuses around the air to fuel ratio numbers and what timing numbers produce peak power. We usually have to change carb. Jetting several times, adjust the idle circuits, and the air-bleeds occasionally have to be changed. We then establish the engine's full horse power and torque numbers at a given rpm limit.

Having your engine dyno tuned will allow it to run its absolute best, and is very important in protecting the engine from potential damage caused by the carburetor running excessively rich or lean. This also establishes the engine's hp output and max rpm.These numbers are very important to know. There is one more value we consider just as important to what we have mentioned above. An engine that has been dyno tuned has also been validated to be in perfect operating condition.

This is something that running the engine on a test mule can't provide. Any problems the engine may have will show up during the dyno tuning process.

We have on rare occasion seen a popular combination show hp numbers that were not where they should be. Some of these problems give no indication other than reduced hp numbers. We find and fix such problems. The problem may be something simple and easy to find and in some cases very difficult to pinpoint. We will not send the engine out until it's perfect.

When engines are dyno tuned, the chances of you having a problem are near non-existent. Unforeseen problems may still, occur but they are rare. We have kept the cost on this extensive procedure low to not only make it affordable, but it gives us great peace of mind knowing the engine will be in perfect operating condition when it is received. Pictured below is one of our actual Super Flow dyno's.This is a 2016 model and highly advanced compared to the much older models many shops have. We have two of these in use at our shop.

The Super Flow is the best dyno in the industry. This engine is warranted, with limitations and exclusions as set forth below, for two years from date of sale. Keep the crate your engine came in to ensure a safe return to our workshop. Our engines must be used with a rev limiter. Ue to the difficulty of accessing certain engine parts in some vehicles, we are not responsible for the additional time and labor costs you may incur in removing and replacing such parts.Tuning includes jetting or adjusting the carb, ignition timing, or readjusting the rockers. Tuning would also include changing out plugs to optimize temp range for your needs.

Setting ignition timing is also considered tuning. You must check the timing on this engine before it is driven. Detonation damage is evident upon removal of the cyl. The first six months will cover parts and labor, and the second half of the one year period will cover parts only. Marine engines must upgrade to a 4340 crank unless the engine already comes with this, and the ARP-2000 rod bolts. Our engines are custom built to your specifications e. Cam choice, intake, engine color, compression ratio, and upgrades. You can enjoy your engine with occasional spirited driving, as it is well designed for it, but we will not cover damage caused by racing or improper tuning. A rev limiter and fuel to air ratio monitoring device must be used on this engine.The rev limiter should be set to cut off at its peak horsepower or less if you choose, and this should allow many years of service without a problem. Your carb should be tuned to allow the correct fuel to air ratio. This ratio can vary depending on many factors such as altitude, vehicle weight, gearing, type of driving, etc. These values should be in the recommended safe zone.

It is highly recommended that you re-torque the intake manifold. The gasket sealant tends to shrink after a period of time and this may cause the intake bolts to lose their proper torque values. The torque range is approx. The spark plug gaps should all be re-checked.

For those running an HEI distributor, the plug gap should be approx. 040.045 Those running an MSD 6AL unit should gap the plugs to approx.

035.040 These values are very controversial and you may experiment as to what runs best in your engine. Widening the gap too much can put a strain on the ignition components.

Be sure your plug wires are completely fastened onto the spark plugs. If your engine came equipped with a front end accessory setup, we recommend that you check all of the bracket and pulley bolts. It would be rare to find any of them loose, and it should only take a few minutes to check. We would also like you check the belt alignment. Check your flexplate or flywheel bolts.

Check fuel bowl levels in the sight glass on the carb once you have the engine running. Be sure your fuel pressure is set in the correct range. Adjust the choke on the carb.

We would prefer you set the choke to a loose setting. Setting it tightly may allow it do its job better, but can cause engine damage over a period of time due to excess fuel entering the engine upon warm up. Be sure to use a high quality fuel filter. You may not find a problem with any of the items mentioned above, but considering the small amount of time it takes to check them, we find it to be a valuable preventive measure. As it's been said, an ounce of prevention is worth a pound of cure.

Continue reading for more detailed information on timing and carburetion. You must follow the recommendations listed below. Tuning, maintenance, and oil recommendations. This engine must be maintained with oil specifically designed for high performance engines. The life of the engine can be greatly extended if you run a race grade engine oil such as our Schaeffer brand racing oil. We strongly recommend the Schaeffer Micron Moly 20w-50 grade in warm to hot weather or you may run the 10w-30 weight Schaeffer Supreme 7000 series semi synthetic oil in cooler weather. The part number for this oil is 709-06 for the six qt. Case or 709-12 for the full case.After the engine is fully broken in, you may move over the Schaeffer full synthetic oil. The Schaeffer brand oil is very highly rated. It is the only brand of oil we use when dyno tuning. Racing oil must be changed more often than conventional oil. Every 2000 miles or less would be optimal.

We offer a full line of this oil in our other listings. Here is a brief outline of the average additive levels in the Schaeffer Oils as compared to Valvoline VR1. We only use Schaeffer oil in our dyno room, and strongly recommend its use in our engines. The 10W-30 7000 series oil is totally acceptable to use in one of our brand new engines. It will not interfere with the break-in process.

The 20W-50 Micron Moly is also an excellent choice to use in warm weather. 191 Micron Moly Racing Oil. Soluble Moly = 350 ppm. A couple of things worth mentioning: Valvoline VR1 doesn't report any Moly in their oil. Schaeffer uses a soluble form of Moly that bonds to metal under heat, pressure, and movement.

Once fully bonded, it takes over 500,000 psi per square inch. Schaeffer Oil has the best base stocks and additives that make it the best oil on the market.

Oil pressure of 50-60 lbs in the upper rpm range on a fully warmed up engine is nothing to worry about. You may also notice that oil pressure drops at idle to approx 25-30 lbs when the engine is fully warmed up during very hot weather.This is somewhat common and no cause for alarm. If your engine has a Dart block, then it has priority main oiling.

This block routes the oil in a very different pathway compared to a GM block. The mains and rod bearings as well as the crankshaft are well protected with an ample supply of oil even when the oil pressure numbers are lower than you think they should be. There are many special additives in race grade oils that are not in conventional oil. These additives are very valuable for high performance engines.

Add anything to racing oil. This oil has exactly what is needed to protect a high performance engine. Some of these oils will state that they are low or possibly non-detergent, and that is a desirable trait of racing oil. The anti-foaming agents in race grade oils are much better than what you would find in conventional motor oil. Race grade oils have higher than normal amounts of the zinc compounds in them, and there are many components in the engine that can make great use of these additives.

This engine does not include a fuel pump. This engine is best suited to operate with an electric fuel pump, with a pressure regulator set at 6-6.5 psi. A chrome block off plate will be installed on the engine.

If you decide to run a high volume mechanical fuel pump on this engine, then you must use the special polymer fuel pump rod that we offer, and you must also use a fuel pressure regulator, and gauge, set to approx. Only use engine oils with high levels of zinc compounds in them when running a mechanical fuel pump. This will protect the eccentric fuel pump lobe on the camshaft. We strongly recommend the Schaeffer Racing oil. See our other listings for this oil.

You must use a rev-limiter on this engine. A rev-limiter will allow you the freedom to drive without having to monitor the tach. Every car from the factory has this feature.

We strongly recommend using a crankcase ventilation system to pull gases from the crankcase. The exhaust evac system we recommend is made by Moroso. The benefits are numerous as compared to the typical pcv system. Oil leaks are greatly reduced by using the exhaust evac system. Engine break in: As soon as your engine is installed. Check and reset the timing if needed. Drive safely please but keep your engine under load more than normal and bring the rpm up and back down to seat the rings much better and faster. This allows the rings to expand in a perfect circle and with greater pressure against the cylinder walls to establish an even wear pattern. This is why race engines are dynoed.To put a good number of passes on the engine under heavy load, as this will partially seat the rings very quickly, making the engine somewhat ready for racing. Failing to do this not only delays the break-in, but can permanently stop the engine from establishing a good wear pattern on the cylinder walls. If you have opted for our dyno-tuned version of this engine, then ring seating will be partially established. The dyno has a computer controlled break-in mode that we use before doing any dyno testing for power output. Should you opt for the dyno tuning package, it does not mean that your engine is ready for full synthetic racing oil.

Your engine will continue to seat the rings in to an even higher degree after 300-500 miles of driving. You must prime your new oil filter. Priming is not needed when changing oil on a well broken-in warm engine that has been running moments before changing the oil. If your new engine has been sitting around for weeks, or possibly months, then you must prime the oil filter.

You must be sure that your air to fuel ratio is correct. We strongly recommend purchasing a fuel to air ratio monitor. Proper carb jetting is also a must.If you are using your own carb. On this engine, then you must be sure the fuel to air ratio is correct. If your carb is running too lean, detonation is at your door.

If it is excessively rich, cylinder wash-down from excessive fuel will destroy your bore finish, pistons, and rings quickly, not to mention cause excessive fuel consumption. A tad on the rich side is not a problem and can help resist detonation; a tad on the lean side will generate the most power and increase fuel mileage. The optimal air to fuel ratio is approx.

13:1 Set total timing at 30-34 degrees. Total timing refers to the reading at 4500 rpm with the vac. The closer to the lower number (30 degrees) the total timing is, the safer your engine will be. Do not worry about initial timing, as it will be determined by the total timing. We do not recommend running the vacuum advance with this engine. Be sure to have a high amperage battery and high quality starter. The battery must be 850 cca or more. Use heavy gauge battery cables.This will allow you to control your timing for optimal performance and ease of starting. Do not run regular gas in this engine, no matter how much you have reduced the timing. It may not be enough!

You may have run an old car in the past that pinged and clattered under load for many miles, and this didn't seem to hurt it. Most cars from the 60's and 70's had very low compression, especially when nearly worn out, and this is why the detonation did not destroy the engine. Excessive pinging, spark knock or valve clatter, as it's often referred to, may destroy this engine very quickly. Light pinging now and then is unlikely to do any damage, but it certainly will when there is an excessive amount of it under load. Let any engine with compression numbers above 10:1 clatter and ping for very long, and you will lose the engine due to detonation, and in some cases this can happen very quickly.

Spark Plugs: We recommend the Autolite brand, part number Autolite 3923. Most of our engines include the correct spark plugs.We also offer a premium NGK plug that is highly suitable for this engine when running in very hot climate. Race grade plugs are fine as they have a few features that are desirable for certain types of driving. Keep the temp in the low to middle range. Use a plug that's too hot, and you are once again close to detonation/pre-ignition; use a plug that's too cold and they will foul constantly, run poorly when cruising at low speed, and be difficult to start. You may also use NGK part # NGK 4554, a plug that is one step lower in heat range than the Autolite plug.

The NGK plug is only to be run during very hot weather. You would be amazed at how much better an engine will run with the correct spark plugs installed, but brand name has little do with this. It's more to do with heat range than any other factor. Factors such as outside temp, altitude, compression ratio, and the type of driving you do determine the temp range to run. A slight loss of power is also an issue with plugs that are too cold, as well as possible difficulty in starting.

However, you can have much more serious issues by running plugs with high temp ranges. Keep the engine coolant temp as low as possible, but it is not a problem if it runs as high as 210 on very hot days, as long as it's consistent, and not climbing. Never use any of the modern day type antifreeze formulas that are used in most newer cars. This will most likely destroy the gasket material used in these engines. We have a customer that used the orange colored antifreeze made for Toyota trucks as he happened to have this on hand. This led to a failure of the high quality Felpro intake gaskets. The print seal material was partially dissolved allowing great amounts of coolant into the combustion chamber.This led to a catastrophic engine failure. The correct type of antifreeze to use should be ethylene glycol based, usually green colored. There are some animal safe substitutes on the market that should be ok to use. A mixture of 50/50 or even slightly less antifreeze will cool the engine better than a rich mixture of antifreeze. Keep the engine temp down if possible, but don't worry if you can't get it below 210 on a hot summer day.

The cooler you keep the engine, the lower the risk of detonation. Set engine idle at approx. 900-950, and never too far below this unless you are running the smaller engine cam choices. The reduced size cams would allow for a lower idle speed.

Never let the engine idle for excessively long periods during the break-in period. Do not overfill with engine oil. Slightly less than normal is better than too much, in most cases.Using half a quart less oil can greatly reduce potential oil leaks. This is a common practice in many high performance engines. When setting your carb choke, we recommend setting it on the mild/lean side. It is best for the choke to open up to its full straight up position as quickly as possible.

Keep backing it off until cold starting becomes difficult. Quickfuel brand carbs are best to run. They are also suitable for use on engines running a mechanical or electric fuel pump.

If the choke is set up on the aggressive side, it will create an over-rich condition upon every cold start-up and warm-up. This over-rich condition is very damaging to an engine, and will waste fuel. If you feel you can get by without using the choke, then by all means do without it! The modern day carbs actually do well with very little or no choke. With a few pumps of the throttle and a bit of feathering, the throttle will have you off and going smoothly, in most cases with very little or no choking at all.

Hydraulic roller setups are virtually maintenance-free and require little if any maintenance. Our recommendations will change from time to time. We never stop trying to build a better engine, and we learn from our own experiences and from feedback from our customers.We know there's always room for improvement. We're always working on research and development, as does any successful business. We advise checking out the recommendation section of our engine ads on a regular basis. Not knowing is understandable, but failing to educate yourself on the do's and don'ts is asking for problems.

We suggest joining a few good car forums, as they have a wealth of great information. However, beware of some individuals on forums who think they know it all, and really know very little. Do your research using several sources, and be sure to read between the lines.

You may never have a problem with any of the components, but excessive street driving at cruising speed can adversely affect these components. Solid roller setups on BBC engines should not be driven for excessively long distances or for long periods of time on the street. A weekend of racing at the drag strip would likely have less of an effect on the valve train components than a 100 mile easy drive.

If you do think you will be driving significant numbers of miles, we strongly recommend staying with our hydraulic roller cam package. See our other listings for info on all of our engines. Your engine info will include the balance sheet and other information on this engine such as cam card, and your invoice will show your personal selection of the options offered. Many have asked why we're able to sell such an engine for such a great price. It's because we're a major distribution center for all of the parts used in this engine, as well as a full scale machine shop.

Few machine shops ever get to master-wd pricing. We also believe in keeping our profit levels low enough to allow the working man a chance to build his car the way it should be built. Please see the article below for a more detailed explanation. I'm sure many of you have noticed there are 2 high performance engine builders in Kingsport, TN with similar names, and this has led to a great amount of confusion. We are Skip White Performance, NOT White Performance and Machine.

Due to the name similarity many customers looking for us online inadvertently find them, thinking we are the same company. There is no connection between the two companies. We don't have a problem with free enterprise (competition).

However, when the competition builds their foundation on such things as a name similarity and their supposedly long history of being in business, then we think it's about time we set the record straight. We have owned White Performance since 2003, with the exception of the machine shop, which was owned by Fred White at the time. Due to their limited production capability and many disagreements about the engine building process and workmanship, we opted to open a full scale machine shop of our own a few years later. Fred White began competing against us even though our contract had a non-compete clause in it.

As our business grew, we opened a second, much larger warehouse and machine shop around 2011, located on Brookside Ln. By putting heart and soul in this company, we have become the number one street rod engine builder in the nation. This investor lacks any knowledge of this industry. They continue to use the White Performance & Machine name. Contrary to what is posted on their website, Fred White is no longer associated with the company in any way.

All in all, we have been in this business 16+ years. Skip White's passion has been owning and building street rods for 47 years on a personal level. The knowledge he has gained over time has allowed him to venture into this business and succeed to a very high level. The great pretenders continue capitalizing on our success due to the name similarity, but have been degrading our reputation.

Recently, we have been getting calls nearly on a daily basis from people that now realize there are two shops in this town with very similar names. They complain of serious problems in getting their engines in a timely manner from them. Due to the confusion, there is an increasing amount of negative talk that is starting to reflect on our reputation within the street rod community, when in fact we have a near perfect reputation in this industry. We have become the largest street rod engine builder in the nation.

2-4 weeks, perhaps sooner, depending on the season. Now you know the real story, and we hope this helps with the confusion.

You must have a dock or fork lift. We can have the engine delivered to a residence with lift gate service but at an additional cost. Your engine will be in a crate on a pallet, and you will receive a roll around engine cradle at no additional cost.

The value of the engine cradle is approx. Your engine will also be fully insured. You may also request an invoice at time of checkout. For tech support, please use the "Ask A Question or Contact" tab. Your selection of what type transmission you're going to use with your new engine is very important. I'm going to give you the real lowdown on what transmissions I recommend, as well as the ones I would stay away from. For those building a very mild, (detuned) street rod, (small cam choice, dual plane intake) these recommendations are not as critical. 700R4: Worst possible transmission choice. None, other than there are plenty of them around for a cheap price, and for good reason. Fuel injection does make this trans. It will get you from point A to point B period! Very wide first to second gear spread. First gear is a 3.06 ratio Second is a 1.62 ratio. This nearly equates to skipping from first to third gear with a manual trans.This kills acceleration when these trans go into second gear on a carbureted engine with a healthy cam and large runner intake manifold. Compare this to a TH350. First gear at 2.52 ratio and second gear is 1.52 do the math. The 3.06 first gear is so low that any final gear of above 3.55 or numerically higher will have you right at the max rpm at around 35 mph, only to then have your car fall on its face when it hits second gear, feeling like it skipped a gear.

Wheel spin is uncontrollable upon hard launches, unless you have a very tall final gear, and then you can for sure count on going nowhere quickly when second gear comes in. Overdrive would be totally useless at highway speed regardless of detuning with a tall final gear, unless you were cruising at around 100 mph. Huge cost to build up to a decent street rod level. Don't even consider a stock rebuild to handle 500 hp or more.

Under hard use, the 700R4 will fail quickly. Limited as to what level these can be built up to. High performance transmission builders and parts suppliers don't even recognize this as a serious transmission. More complex to build than a TH350 and far more expensive, especially when built up to handle high hp numbers. Having to run a cumbersome throttle value cable to the carb.

This feature actually serves a good purpose, but if not set properly, it can destroy your transmission quickly. Very critical adjustment, and often overlooked. The overdrive is actually useless with engines running decent size cams relative to the cubic inch, especially with large runner dual plane intakes, and single plane intakes are out of the question with this trans. Stall converters are double the cost of the one run in a TH350.This is not a reliable transmission in a street rod. Lowers the value of your vehicle to some degree, especially on high hp builds.

These transmissions do not belong in most carbureted street rods. You must detune an engine considerably to operate the overdrive and be able to tolerate the first to second gear drop. Could be classified as the worst mismatch of parts known on a true street rod. As a side note, I would like to mention that most of us have owned a regular stock street car with a 700R4 trans, or its electronic likeness, a 4L60E, and didn't find much of an issue with the way they operated, especially if the vehicle was fuel injected. This is because stock car engines are designed to operate totally different in the very low rpm range.They have huge amounts of off idle torque compared to the average carbureted street rod that makes 400 hp or more. This off idle instant torque allows the vehicle to keep its speed up decently when the 700R4 drops into second gear, and the same low rpm also allows the overdrive gear to operate normally at very low rpm. There are other factors that also allow these trans. To operate at low rpm, especially on fuel injected computer driven engines. TH350: Best transmission choice, hands down.

Excellent gear spread between all three gears. Most all transmission shops are capable of building these to at least level 1 or 2. No TV cable to deal with. Stall converters are low in cost, and the selection is broad. Very reliable and simple to repair if needed. Select a final gear that will allow you the best overall performance and one that allows a decent off the line acceleration, and one that will be in a tolerable rpm range at highway speed. You must have the correct stall converter for optimal performance. This can make a huge difference in the way your vehicle accelerates. These are becoming scarce, but there are still plenty of them around, and high performance parts are easily obtained.You may have to go through this long story to your less than knowledgeable friends as to why you didn't choose a 700R4, and when you explain it to them, they may still think you don't know what you're talking about. Very similar to a TH350. Simple to build or repair to stock buildup levels. The TH350 has far more high performance parts available at reasonable costs. Is not a practical choice.

Internal rotating parts (cast iron drum) are very heavy and create a huge drag compared to most any other trans. And this is not a subtle amount of drag. The TH400 is well known to be a heavier duty trans. Than a TH350 but this heavy duty factor was designed more for heavy vehicles that may encounter pulling heavy loads. Only the largest of the GM cars weighing around 5000 lbs had these trans. In them, along with heavy duty pickups, usually 3/4 ton or larger trucks. Even the half ton Chevy trucks didn't come with these in them. They will certainly hold up better than a stock built TH350, but they are not a desirable trans.You can build a TH350 to level two that would be superior to any stock TH400 in every way for about the same cost. You will never see this trans in a true Pro-Street car.

Shops are able to build this trans with ease. Very reliable, and simple to work on.

Not much to go wrong. Decent first to second gear spread. Rotational drag is very low with this trans. Moreso than any automatic on the market. Stall converters are not expensive and many choices available. Two gears, that's the problem. Can only be run in cars that have a very high hp to weight ratio.It would be fair to say a vehicle weighing approx. 3400 lbs would require an engine output of 1000 hp or more to make it a rational choice, and even then, you would still need a decent final gear to get things moving off the line. The first gear in these is somewhat tall. Those running a T-Bucket roadster weighing around 1800 lbs. With a 500 hp or higher engine could make great use of a Powerglide trans.

Having only two gears limits having the best of both worlds when it comes to off the line acceleration and cruising at highway speed. Has a better gear spread than the 700R4 but not as optimal as the TH350. Not much good to say about this trans. It certainly has a place in some special late model applications, but old school Chevy engines is not one of them. Most all the cons you see for the 700R4 exist within this trans.This trans is not a reliable trans. Compared to any of the early GM trans.

No TV cable to deal with or shifting linkage. It has pump pressure control and shifting via electronics. Not much good to say about this expensive trans. It is virtually a 700R4 with a modern twist. Most of the same issues as the 700R4. Terrible choice to run in an old school carbureted engine. Computer controlled engines may require this unless you bypass the car's computer system. Pointless to run such a terrible transmission.If you insist on such a trans, the 4L80E is a better choice, as it has a normal gear spread, and is a much stronger trans. Still pointless to use with an old school carbureted engine. Four and five speed Manual Trans. Excellent acceleration at any speed due to many selective gear ratios.

Finding a gear at any cruising speed to hit it hard is easily accomplished with a manual compared to an automatic. In other words, less loss of power due to slippage as encountered with an automatic trans. For some people, the fun factor of shifting gears is one of the high points of owning a street rod. Simple to change out a clutch if needed. And high performance clutch and flywheel, especially the Tremec Series.

Can be somewhat complex to change over from an auto to a manual trans. If you think your car is going to run faster with a manual versus an auto, you will be greatly disappointed.

The automatic transmission can not only shift much faster, but off line acceleration can be controlled to a much greater degree. This is why most drag cars have automatic transmissions. All things equal, a car equipped with an auto trans will outrun one equipped with a regular street rod manual with great ease.Missing gears when racing can cause damage to your engine, and loss of control of your vehicle should you drop into the previous gear during an aggressive run. Been there a couple times, dropped a valve in brand new Lotus Esprit shifting out of second into first rather than third, and locked up the back wheels on a Dodge Viper shifting into second rather than fourth at high speed. Nearly lost control of the car at around 80 mph.

If you're deciding to run a 5 or 6 speed manual trans because of the overdrive gear, be aware that most engines built with large lopey cams, and single plane intakes running a carb will usually not allow effective use of the overdrive gear. Tremec T56 transmissions are very popular and highly advanced. They tend to be notchy to shift when new. Takes many miles before they become easy to shift.

They can be difficult to install in some early model classic cars, as they are huge compared to early model transmissions. Still about the best manual trans out there, and can handle very high hp levels. Sadly, your wife may not be able to drive your car with a manual. This could be a plus in some cases.Note from Skip White, President. I have reviewed similar 454/468 engines on the market, and I've found many of the parts used to be substandard and overpriced. When I use the term "substandard, " I mean relative to the price charged.

However, some sellers have parts in their engines that are prone to failure in our opinion. The machine work or lack thereof on many of these blocks may also pose a problem. Many vendors sell BBC engines at similar prices, but most of them use crusty old 454 blocks.

These 30-40 year old blocks are past their prime and, even when they were new, made a very poor foundation for an engine generating double the original horsepower. If you see the term "seasoned block" in the build parts list of an engine, that is indicative of of an old junkyard block that's seen many hard miles. For the most part, many of the components used in our engines are far from the lowest cost version on the market. They are in the middle ground, or better. This is why I feel it necessary to mention all of the items in detail used in our engine, as I feel they make the difference in reliability and longevity.If you want to make a true comparison, then you should request a full build sheet, including brand and the actual part number or description of all parts being used, from our competitors. Some of the items used in this engine are actually lower cost/lower grade, but have nothing to do with reliability or longevity of the engine. These lower cost items keep the price reasonable but do not compromise reliability.

For those wanting a higher horse power engine, see our other listings. We have the most advanced machinery available on the market. We torque plate hone the cylinder walls using a state of the art. Very few shops have this model. It not only produces a superior bore finish that allows a faster break-in time, but it also creates a very straight and uniform finish with virtually no distortion or variance in the. This machine cost us approx. Most of the very high end engine builders are now using this model. Those offering high performance engines for sale and not disclosing what machines are used on them is unsettling to me. The item "CHEVY BBC 540 555 STAGE 7.0 TURN KEY ENGINE, DART BLOCK, 724 hp" is in sale since Wednesday, January 20, 2016. This item is in the category "eBay Motors\Parts & Accessories\Car & Truck Parts\Engines & Components\Complete Engines".The seller is "skipwhite" and is located in Kingsport, Tennessee. This item can be shipped worldwide.

- Brand: BBC 540 555 7.0 TK DART SCAT Bravo Comp

- Manufacturer Part Number: 540 555 STAGE 7.0 TURN KEY